Description

Conductive textiles for RF shielding, Sensors

One of the qualifying points of SOLIANI EMC is the internal production of electro-less on different types of fabric materials. The line has the possibility of covering every single fibre with a coating such as nickel, which is stable against corrosion and has a good shielding value.

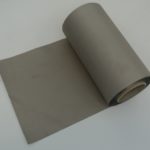

There are currently available fabrics and fabric materials of different types coated in metal. The line permits the values of electrical conductivity from 100 milliohms squared and up, to be obtained.

Materials

Standard fabrics are Static Clean, Gallileo and Pongè, articles in polyester that have weights that range from 60 to 150 grams per square metre after being metal coated. The proportion of pure nickel varies from 12 to 35 grams of metal per square metre.

These fabrics behave differently when exposed to electromagnetic fields and are characterised, compared to competitive products, by the following advantageous reasons:

- High resistance to corrosion due to the lack of copper

- Stability of the superficial resistance value

- Resistance of conductivity even under repeated mechanical or abrasive action and repeated bending.

- Good shielding from low magnetic field frequencies and from those of up to 18 Ghz

- Good mechanical resistance to traction and tearing.This being premised, the fabrics that are metallised may also be those not only of polyester but also of carbon fibre, Nomex, Kevlar and polyamides. These fabrics have been tested to evaluate their different properties such as electromagnetic shielding, their bending in relationship to their endurance; these tests as per precise regulations are available.

Photographs taken at SEM give a true view of the adhesion of the metal to the fibrils as there is the possibility of evaluating the thickness of the filler. A test to evaluate the level of cutaneous irritation according to the ASTM F 719-81 UNI EN ISO 10993 regulation 10TH part, has shown that after 72 hours there is the appearance of some erythema, oedema and necrosis.

Presently we are working on the evolution of deposition of other metals on fabric structures, such as SnO MgO e TiO2.

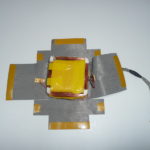

Applications

The evolution of fabrics as structures and of the fibres that make up their electrical and mechanical performance give hope for an evolution of products beyond those already known.